LS-301 Dual Drive Soft Stone Bead Polishing Machine

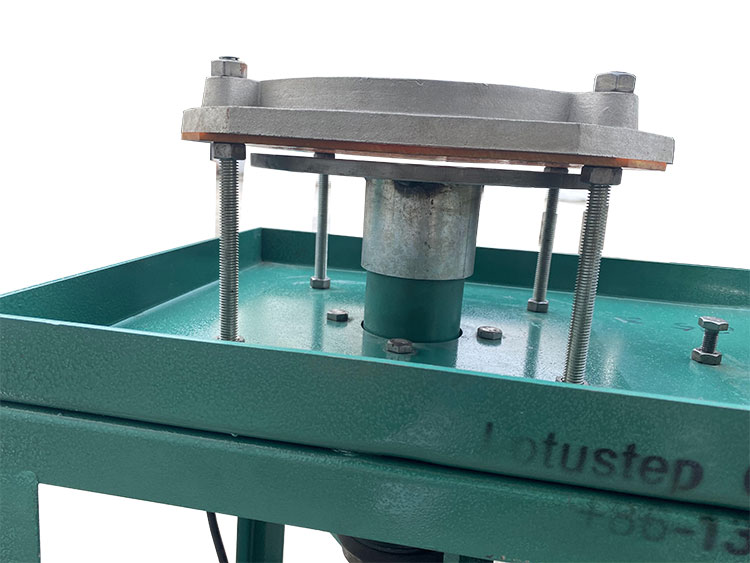

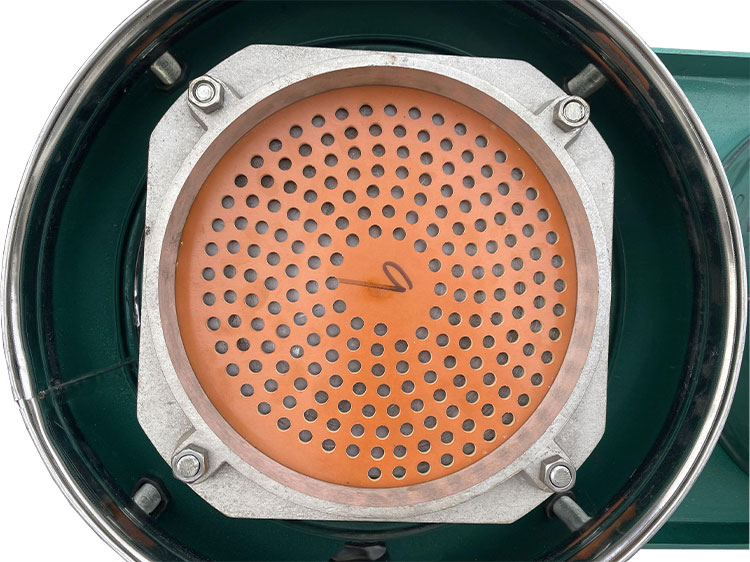

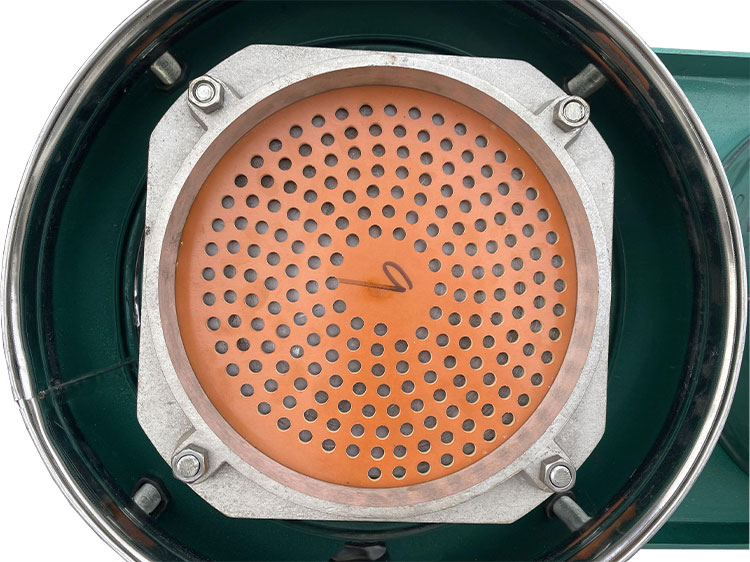

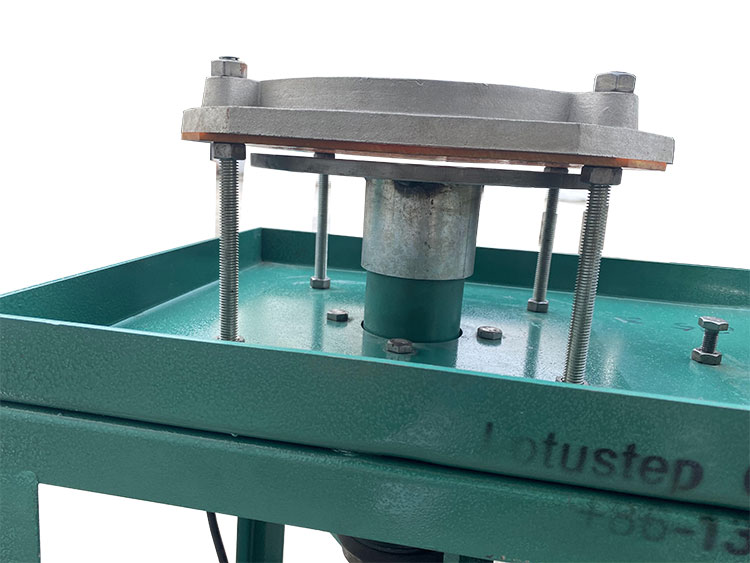

We use a wood disc with holes, each bead is separately polished, one hole with one bead, polish with different grit sandpaper and polishing buff. We suggest start with sandpaper #320,#600,#1000,#1500,#3000, then polishing buff with polishing powder.

The machine can make with a cover protect from dust and noise.(Optional)

LS-301 Dual Drive Soft Stone Bead Polishing Machine

Dual drive soft stone bead polishing machine is designed for turquoise, amber, lapis bead polishing, which is soft in hardness, easy deform and collision broken in a tumbler.

We use a wood disc with holes, each bead is separately polished, one hole with one bead, polish with different grit sandpaper and polishing buff. We suggest start with sandpaper #320,#600,#1000,#1500,#3000, then polishing buff with polishing powder.

The machine can make with a cover protect from dust and noise.(Optional)

Specification of LS-301

Voltage:110/220 V

Power:0.37kw x 2 PCS (1/2 HP)

Speed of Disc:1500 RPM

Overall Size:L110*W75*H80 cm

Each bead is separately polished with sandpaper, polishing buff

Protect from collsion and broken

Recommend use 10'' adhesive backing sandpaper with different grit

Polishing Buff with polishing powder final polish

Accessory can be sandpaper, glue, polishing powder, polishing buff, sponge

The photo below shows how to automatically make round stone bead from rough stone, this machine set can make hard stone bead like jade, agate, quartz bead, and soft bead like turquoise bead, size from 3/4/6/8/10/12/14/16/18/20 mm, 15-50 kg bead one day

Step one:Use 24'' slab saw cut the big rock into small size rock(LS-001-24-A)

Step two:Use 16'' multi blade slab cutting machine, cut small size rock into slabs(LS-002-A)

Step three:Use automatic cut slab into strips machine(LS-006-A)

Steph four:Use automatic cut strips into stone cube(LS-006-B)

Step five:Use stone bead chamfer machine, remove the sharp corner of the bead

(LS-300-1-A)

Step six:Use coarse stone bead milling machine, rough milling, after this step, the bead almost round(LS-300-2-A)

Step seven:Use high precision stone bead milling machine, make bead perfect round

(LS-300-3-A)

Step eight:Use multi needle/tip ultrasonic drilling machine, can drill many beads at one time automatically(LS-100-1800W)

Step nine:Use vibration tumbler polishing machine, polish the drilled beads, make it shiny enough.

The photo below shows how to make stone bead with small batch, 2-5 kg one day.

Step one:Use 12'' manual stone cutting machine, cut stone into slab, strips, cube(LS-007-B)

Step two:Use stone bead chamfer machine, remove the sharp corner of the bead

(LS-300-1-A)

Step three:Use coarse stone bead milling machine, rough milling, after this step, the bead almost round(LS-300-2-A)

Step four:Use high precision stone bead milling machine, make bead perfect round

(LS-300-3-A)

Step five:Use manual bead drilling machine, drill bead one by one(LS-306-B)

Step six:Use vibration tumbler polishing machine, polish the drilled beads, make it shiny enough.